De mm3

à 1 mm3

h

d’usinage/ an

Lacotte Industrie est un expert reconnu de l’usinage de pièces mécaniques de précision de toutes dimensions en métaux durs (acier, titane, inconel) mais également en alliages légers (aluminium) et plastiques. Nous travaillons pour différents domaines très exigeants au niveau des délais, de la qualité et de la traçabilité : aéronautique, robotique industrielle, défense, automobile…

Lacotte Industrie a régulièrement investi dans des moyens de production à la pointe de la technologie. Nous sommes équipés de 4 centres d’usinage 4 axes, une fraiseuse à commande numérique . Ces équipements, gérés par nos techniciens d’usinage de grande compétence, nous permettent de produire des pièces de 1mm³ à 1m³. Nous avons également développé des compétences en tournage dur qui remplace souvent la rectification cylindrique à moindre coût pour des aciers au-delà de 60Hrc.

En 2019, un de nos tours a été équipé d’un bras robotisé. Nous pourrons ainsi garantir à nos clients des prix compétitifs, une exigence de qualité et des temps de cycle de fabrication réduits pour la vie série de leurs pièces.

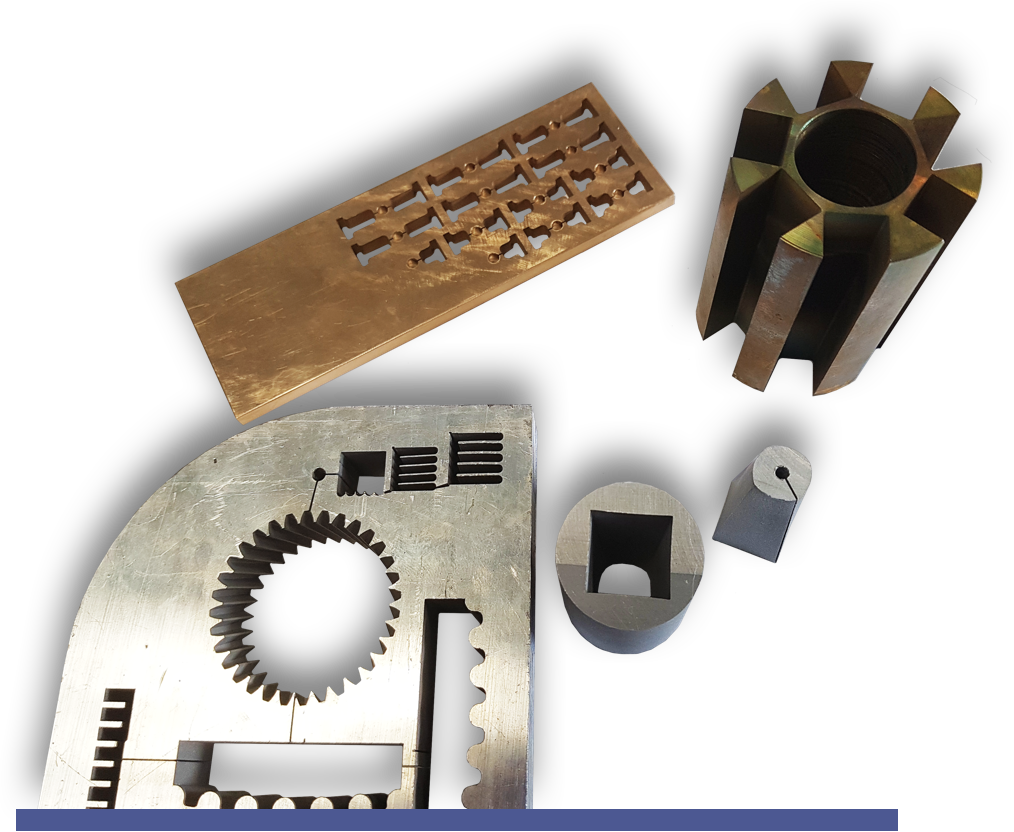

En 2017, Lacotte Industrie a investi dans une technologie complémentaire : l’électro-érosion par découpe fil. Les matrices d’extrusion, les poinçons de découpe sont très fréquemment usinés au fil.

Ce procédé consiste à découper avec un fil calibré et à l’aide de petites décharges une matière conductrice de manière très précise. Le fil peut s’incliner permettant ainsi de créer des pièces avec dépouilles ou avec des profils différents en haut et en bas de la pièce.

Le niveau de précision est de +/-5µm.

L’expertise de l’équipe technique de l’entreprise Lacotte permet de proposer une rectification plane de très haute précision garantissant des états de surface, de contraintes géométriques de planéité ou de parallélisme.

Nous sommes en mesure de rectifier toutes pièces, prototypes, petites ou moyennes séries, quelles que soient les matières utilisée (aluminium, titane, inox, cuivre, bronze, acier, fonte…).

La qualité et le contrôle sont les garants de l’excellence attendue par nos clients. En plus des accréditations systèmes EN9100 et ISO9001, plusieurs de nos clients nous ont accordé des délégations de qualité.

Nos techniciens d’atelier sont directement responsables de la qualité des produits livrés sous la supervision de notre responsable qualité et de nos contrôleurs. Chaque première et dernière pièce sont contrôlées à 100%. La notion de qualité totale fait partie intégrante de l’ADN de Lacotte Industrie.

Nous sommes équipés des moyens de contrôle conventionnels, d’équipements de très grande précision : une machine à mesurer tridimensionnelle MITUTOYO, plusieurs marbres et colonnes de mesure.

Lacotte Industrie intègre des sous-ensembles d’outillage ou de pièces mécaniques et hydrauliques afin de fournir à nos clients des produits finis prêts à être assemblés sur leurs produits ou dans leurs usines. Ce sont par exemple des éléments de moules, des effecteurs de robot, des calibres de contrôle, des outillages de manutention …

Au fil des ans Lacotte a développer une expertise dans le domaine des moyens de levage et de manutention spécifiques