Lacotte Industrie déploie un vaste ensemble de savoir-faire complémentaires dans le domaine de la mécanique et de la chaudronnerie pour accompagner ses clients à toutes les étapes de la vie du produit : prototypage, industrialisation, optimisation, gestion de vie série, pièces de rechange jusqu’à l’a fin de vie du produit.

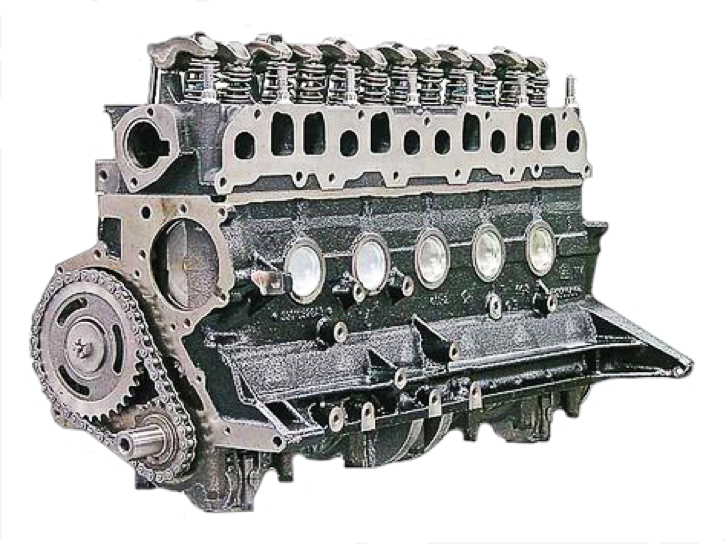

RÉTRO INGÉNIERIE ET RÉPARATION

En fin de vie d’un produit, pour la maintenance de vieille machines spéciales ou de barrage hydraulique par exemple, nous proposons à nos clients de refaire les pièces de rechange à partir de modèles usagés ou bien de réparer ces pièces afin de leur donner une seconde vie.

PROTOTYPAGE ET PIÈCE UNIQUE

Que ce soit pour la fabrication de prototypes industriels ou des pièces uniques pour des machines spéciales Lacotte Industrie travaille quotidiennement avec ses clients sur ces sujets.

Nous lançons en production plus de 1000 nouveaux produits par an.

INDUSTRIALISATION

Nous accompagnons nos clients industriel et aéronautique lors de la phase de présérie afin d’optimiser l’industrialisation.

Nous sommes alors force de proposition sur de nombreux sujets comme les outillages de fabrication, les matières premières , les traitements thermiques, traitement de surface et autres procédés utilisés, les formes et contraintes géométrique… Tout ceci dans un esprit d’optimisation des coûts pour nos clients.

GESTION DE SUPPLY CHAIN

Certaines pièces complexes peuvent nécessiter des traitements ou des opérations effectuées en dehors des murs de notre entreprise. Nous nous sommes donc entourés de partenaires fiables sur le long terme avec lesquels nous partageons les mêmes engagements de qualité et de service.

CONCEPTION EN FABRICATION ADDITIVE

La fabrication additive ou impression 3D est composée de nombreuses technologies encore peu connues. Lacotte industrie a développé une expertise dans ce domaine propose à ses clients un service de réingénierie ou d’étude alliant les technologies traditionnelles et ces nouvelles technologies dans une optiques d’industrialisation et d’optimisation des coûts.

Nous travaillons avec des fournisseurs variés dans ce domaine afin d’être à même de proposer le panel complet des technologies disponibles et ce afin de choisir la plus adapté à l’application étudiée.